-

Phone:410-778-3360

-

Poured In Place

Safety, Accessibility and Durability are the most important elements to consider when choosing a playground safety surface. Statistically, 75% to 80% of injuries to children on playgrounds occur when a child falls to an unsafe surface. The safety surface you choose will be the most important decision you will make concerning your playground project.

Our system is best installed over asphalt, concrete or a compacted crush stone sub-base. It is comprised of 2 layers, a cushion layer of 100% post-consumer recycled SBR rubber and a top decorative recycled post-industrial EPDM layer. The cushioning thickness can be customized per installation while the top layer allows for creative freedom.

An East Coast Safety Surfacing Inc. poured-in-place system installed will make your playground, pool deck, walkway or any other application attractive and safer to use while complying with stringent commercial safety regulations and standards. This will guarantee a secure and enjoyable play space for all. Our system meets or exceeds CPSC & ADA Guidelines ensuring that it provides superior impact absorption while being fully accessible to everyone. Its low maintenance ensures consistent fall protection unlike loose fill options that require daily attention and maintenance making poured in place surfacing more durable in the long run.

It's imperative to keep critical fall height requirements in mind. The higher the equipment, and the risk of injury from a fall, the thicker the playground surface needs to be. With its excellent impact absorption and varying levels of thickness, poured-in-place surfacing is a great and safe option.

With a wide range of color options, poured-in-place rubber surfacing allows playground designers to be very playful in their designs, adding an element of graphic fun or themed designs. The possibilities are endless!

Surfacing is extremely important in ensuring accessibility to playgrounds for individuals with disabilities. The choice of surfacing can significantly impact the ability of all children, including those with mobility aids like wheelchairs or walkers, to access and enjoy the playground. Our poured-in-place safety surfacing provides a seamless, non-slip surface which is fully accessible to everyone, meeting all the ADA Guidelines. Our system eliminates any tripping hazards, further enhancing safety and accessibility.

We will only use the best materials along with highly trained and experienced installers to achieve the ultimate quality in our poured-in-place systems. We have installed thousands of projects along the East Coast of the U.S. In addition to installing our system it is an excellent way to make use of recycled materials. Properly installing playground surfacing can transform an ordinary play area into a safe, inclusive, and inviting space for children to explore, learn, and thrive.

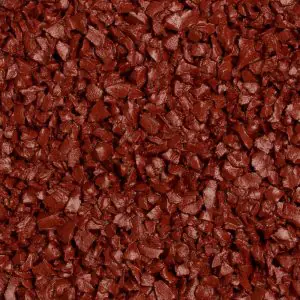

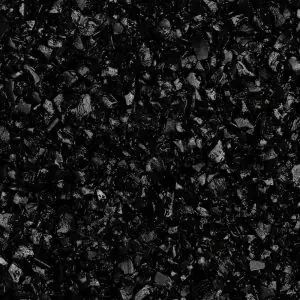

You should consider the type of binder being used when selecting your colors. The aromatic binder will add a yellow hue to the color. This ambering will wear off over time but you may see resilient color differences for a longer period. An aliphatic binder will allow the chosen color to remain stable. Any of these colors can be mixed in combination with other colors to achieve a blended, speckled look. A percentage of black mixed with a color or mixture of colors will camouflage dirt and will reduce the cost.

Terra Cotta

Green

Black

Blue

Beige

Blue & Black

Green & Black

Beige & Black

Terra Cotta & Black

Teal

Purple

Orange

Yellow

Brown

Eggshell

Gold

Light Blue

Grey

Light Green

Capri Blue

Turquoise

Patina Green

Charcoal

Reseda Green